Sheet Metal Fabrication Needs

What is sheet metal fabrication?

Sheet metal fabrication is a process in which a design is created based on which a typically thin, flat piece of sheet metal is cut, bent and assembled into desired parts and structures.

Sheet Metal Fabrication Process at VLTPL: Design to Coating

There are three primary steps in the fabrication process – Module, Forming and Assembly. We strictly follow these processes to guarantee the production of a high-quality product.

Services

Design & Module

In Venkateshwara Laser Tech, we create sheet metal modules using SolidWorks to design, make models and simulate sheet metal parts and assemblies. These are specifically used in the fabrication of products like ductwork, enclosures, and panels. The module typically includes features such as bend allowances, flat patterns, and material libraries. The use of a sheet metal module can greatly speed up the design process and improve the accuracy of the final product.

Prototype

In this step, we test and verify the design to make a sample model of the final product based on the desired specifications and requirements mentioned by the customer. It helps to identify any potential issues or limitations and make necessary modifications before going into full-scale production.

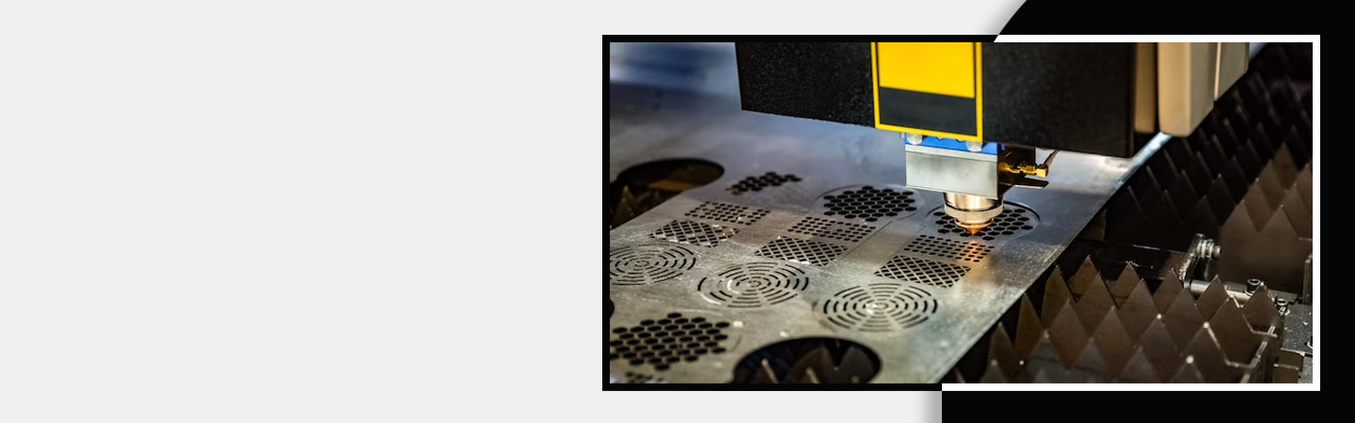

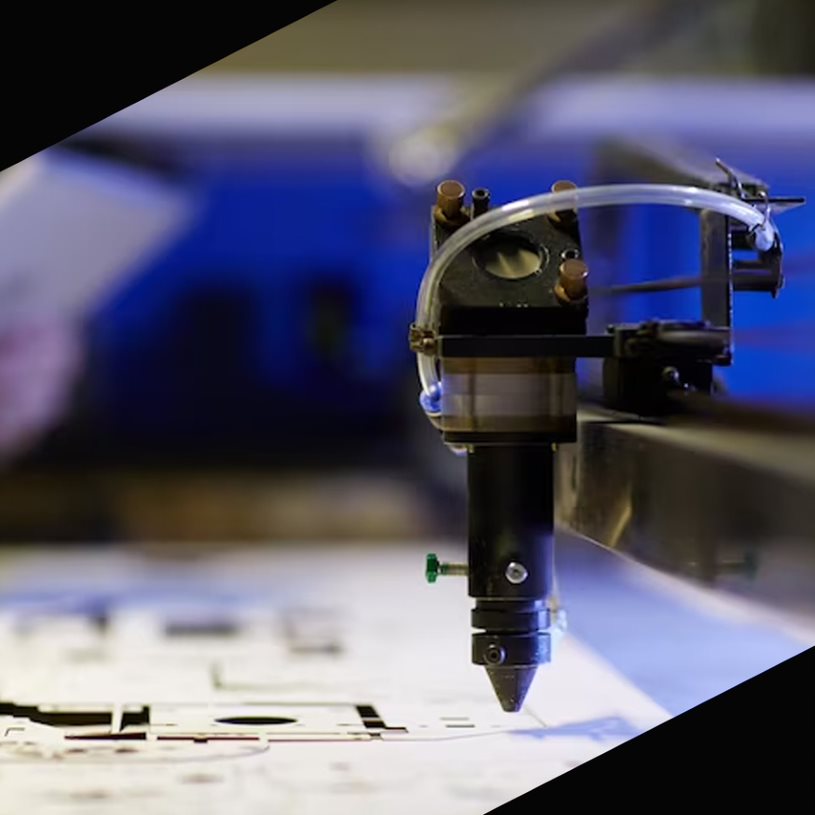

Laser-Cutting

Using advanced CNC laser cutting machines and fibre laser metal tube cutting machines, we cut and shape metal sheets to get the desired product. The laser cutter is programmed with the necessary cutting parameters such as laser power and speed to get the specified material thickness, edge quality and smooth finish.

Bending/Forming

In this step, we shape the material into the desired form by applying force. Break pressing, roll bending and air bending are the various methods involved. At VLTPL, we use advanced Tandem Press Brake machines to complete this bending process. The choice of the method varies depending on the type of material, thickness, size and shape required.

Assembly Fabrication & Welding

The assembly of components is the final step in sheet metal fabrication which is a process of joining or fusing multiple metal components bent or cut to form the final product. This can be done through a variety of methods, such as welding, bolting, or fastening with adhesives. In Venkateshwara Laser Tech we use different types of welding to join the parts.

Coating

This process involves cleaning and preparing of the surface of the metal, primer and coating application is done using methods such as spraying, dipping or electrodeposition. The coating is allowed to dry and harden. The product is finally delivered after quality inspection.